edefining Wet Process Reliability: BLADDER, WF for Next-Generation Wafer and Panel Equipment

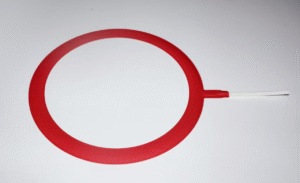

In the race toward sub-5nm semiconductor manufacturing, every drop of chemical precision defines the future of chip performance. At the heart of this precision lies a silent enabler: BLADDER, WF by Zhange. Acting as the “flexible heart” of advanced wet process tools, our bladder technology is setting new reliability standards for global fabs.

The Precision Challenge of Wet Processes

-

Cleaning: Single-wafer cleaning demands 0.1 μm particle removal within 30 seconds, with fluid pressure deviation below 0.05%.

-

Etching: Atomic-level anisotropic etching requires angle accuracy within ±0.5° and chamber temperature control under ±0.3°C.

-

Stripping: Photoresist removal at 120 nm/min ±5%, while resisting ozone and solvent alternation, is critical for defect-free wafers.

Each of these processes relies on dynamic sealing, intelligent pressure buffering, and superior chemical resistance—areas where BLADDER, WF delivers unmatched value.

Three Core Values of BLADDER, WF

-

Dynamic Sealing Excellence

-

Multi-layer fluoro-silicone composite structure

-

Over 100,000 expansion cycles in pH 1–14 environments

-

Proven to cut cross-contamination rates by 87% in wafer cleaning modules

-

-

Intelligent Pressure Buffering

-

Embedded piezoelectric sensing film with <5 ms response time

-

Real-time regulation between 0.01–0.5 MPa

-

Achieved wafer-edge etching uniformity of 98.7%

PVD Wafer Sputtering – BLADDER,WF

-

Trusted by Leading Wafer and Panel Equipment

The BLADDER, WF solution is now embedded in world-class tools, powering breakthroughs in yield and process stability:

-

Wafer Sputtering – Apollo 300

-

Wafer Sputtering – Apollo 200

-

Wafer Plating – Stratus? P300

-

Wafer Plating – Stratus? S200

-

Panel Plating – Stratus? P500

From sputtering to plating, both wafer and panel platforms depend on the unmatched reliability of our bladder solutions.

Conclusion

As Moore’s Law pushes closer to its physical limits, every 0.1% yield improvement means millions in cost savings. Zhange’s BLADDER, WF has already enabled multiple semiconductor leaders to upgrade their wet process capabilities.

When precision meets durability, BLADDER, WF becomes more than a component—it becomes the foundation of next-generation semiconductor reliability.